Robots can fail due to

- Human error

- Control panel problems (PLC, Network)

- Mechanical failures

- Electrical failures

- Environmental factors like power outages

Failures can lead to human injury and sometimes even death, as well as costly downtime.

Common Root Causes for Robot Failures:

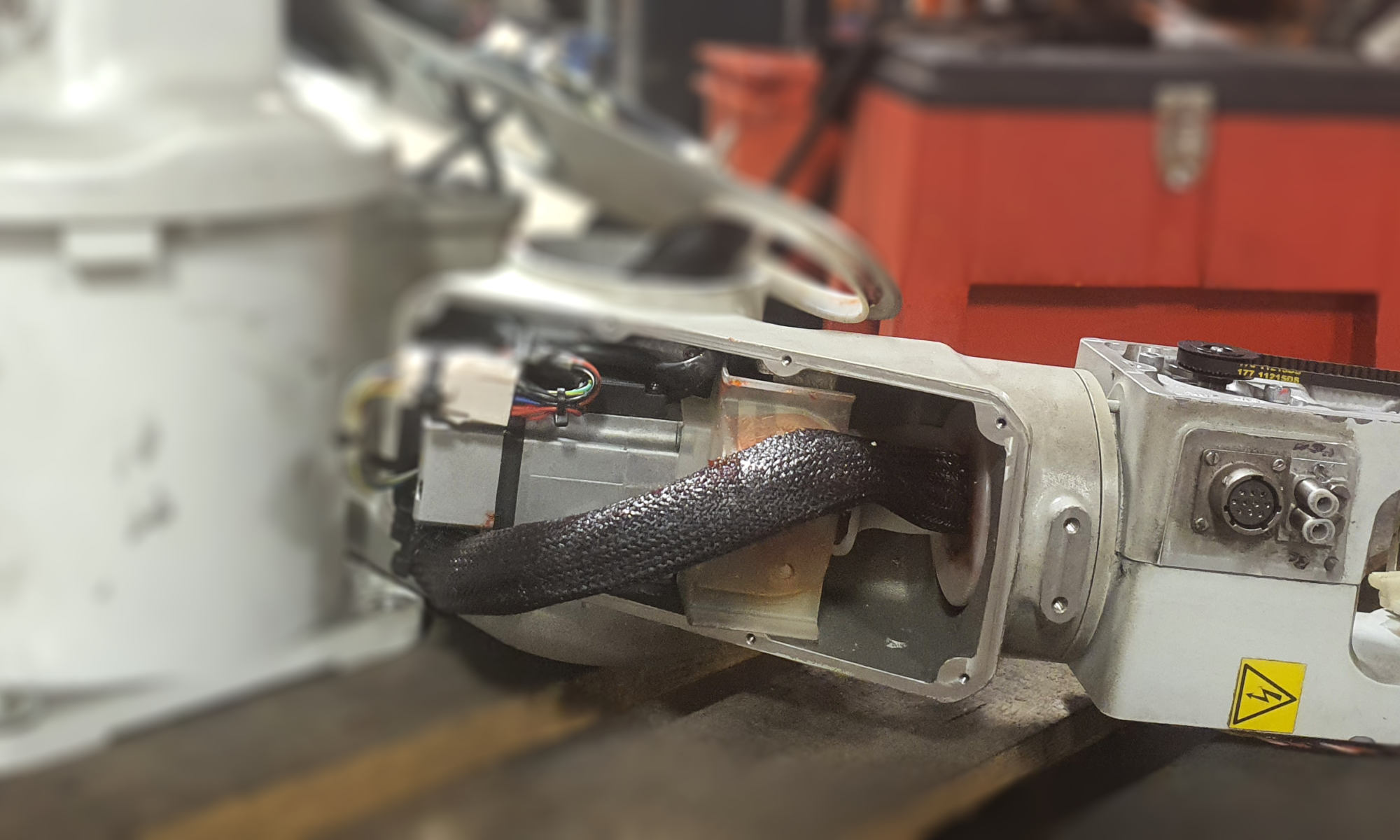

Cable Dress Packs, as simple as it sounds, cable management dress packs are often neglected. Problems are generated because the movement of the robot generates tangles and tension that can lead to cable breaks. We sell best in class Reiku Dress Pack Systems and can install.

Programming: To function properly, robots require programming specific to the application and environment in which they operate. Incorrect programming or activation of the teach pendant or control panel can lead to a robot error that may expose employees to the risk of injury.

Maintenance: Without proper preventative maintenance programs common failures in gear boxes, motors, internal harnesses and simple battery failures or over heating due to old dirty fans and clogged filters cause serious down time. We have PM programs that keep your robots running and maximize both uptime and robot life.

Skilled technicians and engineers at FSD not only respond to critical robot repairs but assist customers in developing better preventative maintenance programs.

Contact us today for all your robot service, support and spare part needs sales@factorysurplusdirect.com