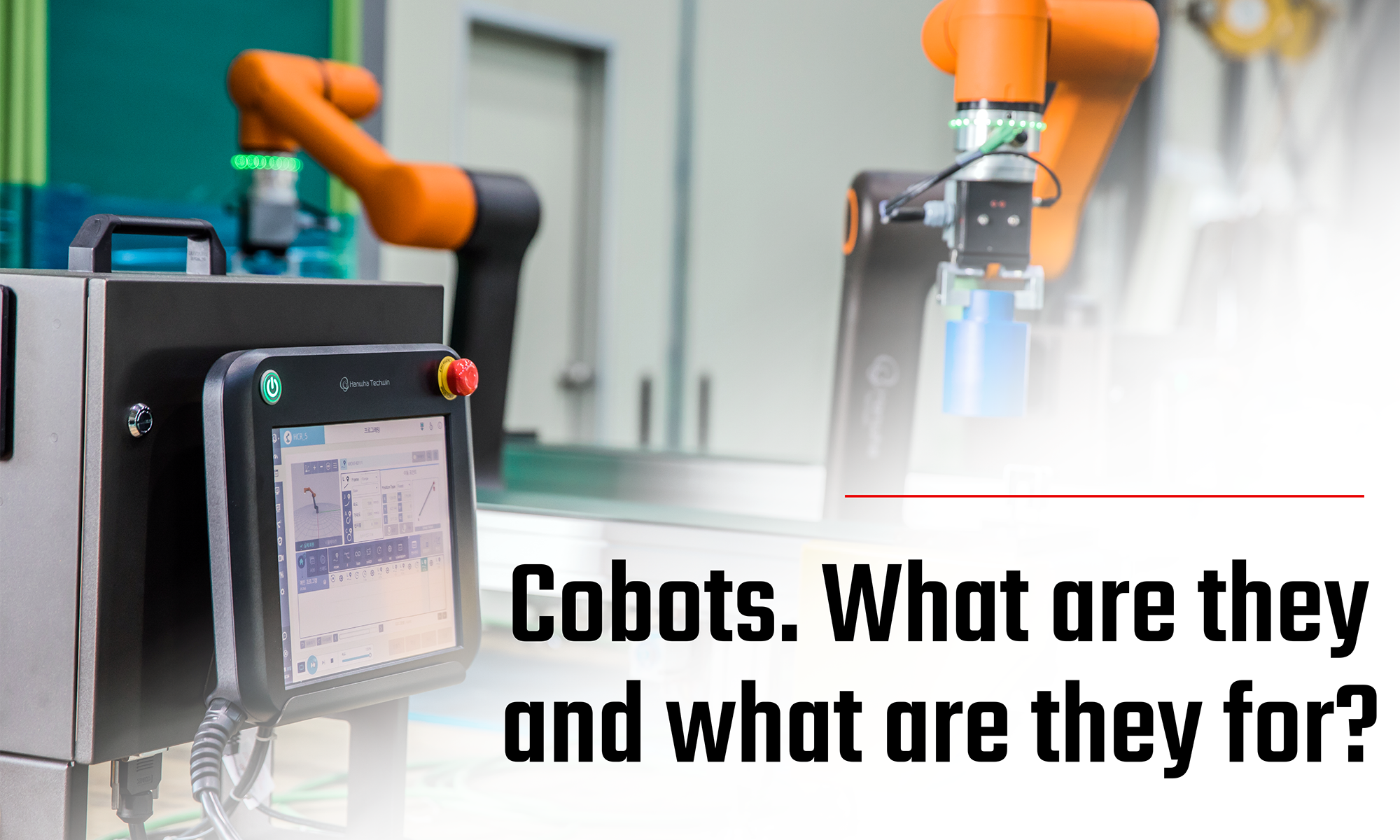

There are still many people who wonder what a cobot is . Well, cobots are collaborative robots that serve to automate industrial processes , whether they are repetitive, manual processes or that endanger people.

Many companies are already betting on the use of collaborative robots in industrial processes. They provide precision and optimization to the processes, resulting in higher quality and productivity production chains.

They are the new generation of robots, which were born to work together with the operators, with the idea of being able to adapt them to different work processes with great ease.

These are completely safe robots for humans, since they are designed for this purpose, working side by side together with human personnel , they are even capable of interacting with them. However, the label of collaborative is not only given by security. It is also about ease of use, adaptability and accessibility. They can be programmed for different functions very easily, there is no need for special training or high qualification to be able to take charge of programming a cobot. They are provided with a very intuitive interface, with which any operator can move without any problem.

Cobots can carry out almost any type of work , thanks to the full range of collaborative accessories that can be provided. Normally they will be used to perform those tasks that are more repetitive and therefore heavier and monotonous to be performed by the operators. In addition, they can perform tasks that can pose a health risk, or those that require extreme temperatures or with sharp or toxic parts for humans.

Their design is light and compact, so they can be easily adapted to any production center, working even in tight spaces.

Five immediate advantages of Hanwha HCR Cobots for your business

Flexibility

The low weight of the cobots, will allow you to move them very easily to be able to integrate them into new processes. So you can automate any task within your company. Even if a quick change is required or when we talk about small batches.

Simple to configure

It is so easy to use, that even mounting an entire arm for the first time can be done without difficulty. Assembling the entire arm and programming it for a simple task will take less than an hour.

Programming

The cobot is provided with a 3d interface, with which any operator without any programming experience can quickly program the robotic arm. It is as simple as moving the arm to the desired points or touching the arrows on the touch screen tablet. The whole process is intuitive, fast and simple.

Security

You can incorporate cobots in your company without creating fenced spaces or security protections, after a risk assessment. They are equipped with a series of devices that make them safe for operators.

Amortization

If you think that automation is an expensive process and that it is not within the reach of anyone, perhaps it is time to rethink it. Cobots are amortized in a short period of time. It is because, thanks to its design, it is possible to do without other costs associated with automation, such as the large infrastructure of traditional robots, security fences, etc.

Cobots can automate virtually everything

Thanks to the flexibility of cobots and the wide range of accessories they have, we can say that cobots can automate almost any industrial process. They are economical even in the assembly of small batches, since it is a highly adaptable robotic arm. It can do: painting, labeling, screwing, packaging, molding, injection, polishing …

Packaging and palletizing

Let the cobot do the work and all shipments will always be properly packaged and taped.

Laboratory analysis

You can increase the degree of objectivity in tests and analyzes with the help of a cobot.

Injection molding

Cobots can be used in all polymer production tasks, with great precision.

Screwing

You will improve the quality and precision of the products, if the cobot is in charge of always making the same movement with the same degree of force and speed.

Gluing and welding

The cobot will bring high quality to the gluing and welding processes by injecting material, as well as perform welds with great precision.

Polishing

The cobots polish and sand even curved and irregular surfaces, with a constant and adjustable force to obtain a perfect result.

Mounting

Cobots can effortlessly assemble a wide variety of materials, such as wood, plastics and metals. Resulting in a perfect precision assembly. Improving the result of the entire process, increasing quality and speed.

Machinery supervision

Cobots can carry out machinery monitoring functions, easily adapting within the production line.

QA

Cobots are provided with a camera that can be used to review and identify faulty parts within a production chain. Increasing the quality of the product, and avoiding shipping and packaging.

Pick and Place

Cobots can take care of all the applications that are required in the pick and place. In this way, the cycles will be faster, increasing the quality and productivity in the process.