Unlocking robotics’ potential – Design strategies to boost machine-tending productivity

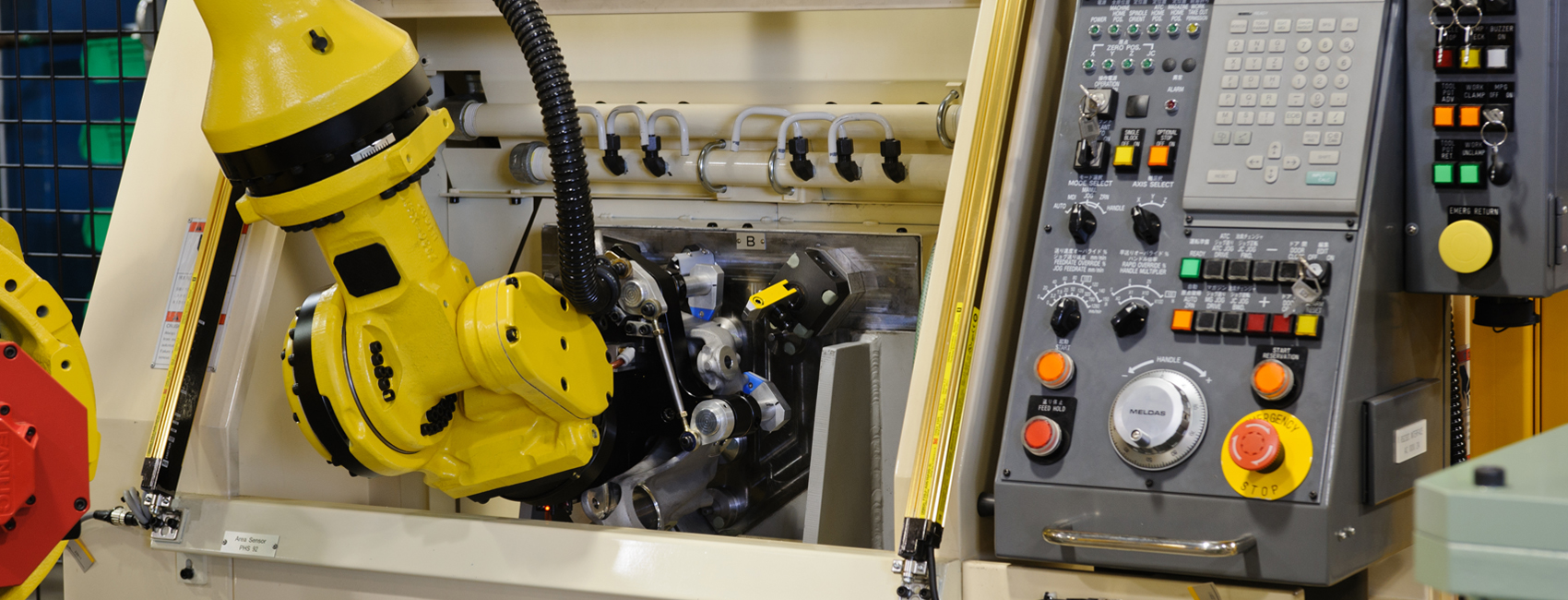

From turning machines to machining centres to presses and press brakes, the evolution of robotic automation continues to address stringent demands, driving industries forward.

Once used in very controlled environments where low-mix/high-volume production was the only viable and cost-effective option for reasonable ROI, more affordable and extremely capable robots have opened the door to highly flexible production environments, fostering greater yields.

To better fill the uptick in consumer product variety, create agile supply chains, and adapt to labour shortages, manufacturers are complementing current operations with versatile robots and their peripheral technologies to create intelligent factories capable of repetitive high-mix production. Because of their perceived ROI over a given payback period, the use of industrial and collaborative robots alike for machine tending continues to be a front-runner for company leaders looking to quickly address dull, dirty, dangerous, and difficult jobs, freeing workers for higher-value-added tasks.

Whether loading/unloading a CNC machine or tending another piece of equipment for grinding, stamping, or trimming, highly repeatable robots are helping to orient and transport parts, minimizing human error, improving worker safety, optimizing system utilization, and facilitating greater efficiency.

Strategic Robotic System Design

Despite the growing use of robotics, each application requires careful consideration where workcell design is concerned. To unlock the full potential value of these automated systems, manufacturers should evaluate the various automation components.

Robot Type

Choosing the proper robot model to complement the existing workspace, along with the weight, size, and manipulation requirements of the part, is key.

First, it is helpful to have a clear grasp of where the robot will be placed. Compact industrial robots that are easily redeployed can be integrated into a machine tool itself, while larger streamlined arms can be positioned outside of a CNC machine’s sliding door or on a mobile platform, tending operations on an as-needed basis.

With robot placement in mind, it is also important to note the existing environment requirements. For example, will human workers be present in or near the robot work envelope? If so, a collaborative-style robot (cobot) could be used. This could entail the use of a cobot that is inherently safe by design and capable of working safely with (or in close proximity to) human workers, or it could mean the implementation of an industrial robot equipped to work collaboratively via one of the four modes of collaboration: safety-monitored stop, speed and separation monitoring, power and force limiting, and hand guiding.

A hybrid option serves to close the gap between operator safety and speed, increasing cycle time with the addition of a safety device such as a scanner, light barrier, or safety mat. These devices can help the robot detect human presence in the work envelope, slowing the robot when necessary. Either way, the determination to use a cobot or an industrial robot with collaborative features should always be based on the completion of a thorough risk assessment.

The condition of the workspace also should be noted because many machine-tending environments tend to be harsh. In facilities where humidity, dust, and water are present, it is beneficial for manufacturers to implement an IP67-rated robot. To facilitate greater layout flexibility without losing capability, manufacturers in these settings are turning to higher-payload, IP67-rated collaborative robots that offer robust programming options.

Mounting Flexibility

To allow for maximum robot reach, it is best to keep the base as close as possible to the equipment being tended or the part being processed. Bases can be fixed or mobile for easy redeployment.

Most robots are lagged to the floor, but sometimes it’s necessary to accommodate unique floor space layouts. For example, top loading, where a robot “sits” on top of a machine, is quite popular for machine- tending applications. In situations like this, shelf-mounted robots with extended- reach capability far below the robot base are ideal. Likewise, a robot installed in the overhead position is well-suited for servicing two machines, often reducing cycle time and costs.

When greater flexibility is needed for high-throughput operations, a linear-motion robot track can be advantageous, adding a seventh axis of motion to the robot’s operating range. Often used for machine tending in the overhead position to improve machine access, optimize floor space, and extend the work envelope (sometimes doubling, tripling, and even quadrupling the space), robot tracks and rails provide exceptional speed, repeatability, and rigidity.

Robots in this configuration can be installed in various positions (floor-, wall-, and ceiling-mounted), maximizing the robot reach while offering optimum load distribution.

For tasks where having a dedicated robot does not make sense, a greater number of highly flexible autonomous mobile robots (AMRs) are now being used. Replacing less sophisticated fixed-routed automated guided vehicles (AGVs), AMRs combine innovative technologies (LiDAR sensors, vision systems, custom tooling) to equip robots with a high degree of skill and autonomy. These robotic platforms, which can move on their own through a facility to the task they are assigned, make it easy for manufacturers to redeploy industrial and collaborative robots around factories for machine tending where needed.

While the initial setup for AMRs may be more difficult and costly than installing a robot on a stationary riser, for example, the use of AMRs can assist with rapid-scale production during periods of demand volatility. Conversely, stationary robots equipped to work collaboratively can facilitate the loading/unloading of items on and off AMRs for enhanced flexibility in high-mix/low-volume production. Using robots in this way is another option to quickly, accurately, and ergonomically handle parts for organized material transfer and consistent throughput.

End-of-Arm Tooling

One of the most complicated aspects of machine tending is how a robot grasps a part.

Whether it’s a pneumatic, magnetic, electric, or hydraulic gripper, the design of the end-of-arm tool (EOAT) is of the utmost importance, and special consideration should be given to the grasping point.

At this point, these questions need answered:

- How fragile is the part?

- Can the part surface be marred?

- Is there an interference that the EOAT might impose when handling or loading the part?

To empower shops with the peripheral tools needed to adapt to changing production requirements quickly, robot suppliers and gripper manufacturers are partnering to provide off-the-shelf ecosystems for ISO-compliant gripper packages that often are easy to install and program. Typically used for collaborative applications, most of these plug-and-play options come standard with plastic fingers that are well-suited for low-weight, easy-to-pick parts.

While there are a lot of standard EOAT options, unique grippers with custom-machined aluminum or steel fingers that accommodate the weight and shape of the part to be tended may be required.

To save time and reduce costs, savvy manufacturers may benefit from 3D-printing gripper fingers in-house. For high-mix production environments, where one robot will be tending to multiple part sizes, it is often wise to invest in a tool changer, because it saves valuable time and resources.

Part Buffering Stations

Determining how a part will be presented to and disposed of by the robot (pre- and post-machining) is vital to the success of any machine-tending task. Depending on part size and dimensions, configurable trays, drawer systems, conveyors, and bins frequently are used.

If a robot needs to grab a raw part, localization is needed so that the part can be retrieved correctly. The trick here is to find balance between convenience and flexibility.

A dedicated drawer or racking system is a relatively simple option and is well-suited for use on the same type of part over long periods.

Regardless of the option chosen, to achieve the fastest ROI, it is important to position the robot at the optimal distance for part loading and unloading, as well as test how the part presenter works in conjunction with the gripper.

Vision Capability

To overcome costly bottlenecks for tasks such as loading/unloading, as well as for handling randomly presented parts, manufacturers have many pre-engineered 2D and 3D vision options for robot guidance. While one could assume that a more structured environment is better-suited for a 2D vision system and that a more chaotic, random environment is more ideal for a 3D vision system, determining the proper option for use really depends on product specifications and standards and environment, as well as the end result trying to be achieved.

Along with this, decision-makers may want to consider whether a camera should be mounted on the robot or off of the robot. While this usually is determined by the application, it is sometimes forced by the camera technology because some 3D vision systems require an off-the-robot camera and some 2D options can use either. It is important to note that off-the-robot cameras typically make cable management easier, provide a larger field of view, and facilitate parallel operations.

Again, to ensure they are choosing the proper robot and peripherals, manufacturers should have a thorough risk assessment performed by an experienced robot supplier or integrator. This will go a long way in answering system configuration questions, as well as adhering to ISO standards for the utmost safety.

Unlocking Greater Potential

Implementing robotic automation for machine tending can enable multi-shift operation, minimize manual product transfer damage, free human workers for higher-value-added tasks, and optimize product work flow in manufacturing facilities.

From greater precision and consistency to increased efficiency and quality, robots provide considerable benefits to labour-intensive tasks. Moreover, robust yet easy-to-program robots equipped with multi-function EOAT and other innovative peripherals are readily deployed and redeployed on demand, adding greater flexibility on the shop floor to meet increased customer demands for various materials in nearly every shape and size.

By: Dean Elkins